Shengyang Medical Technology teaches you how to judge high quality acupuncture needles

诚信经营 顾客至上

At the intersection of traditional Chinese medicine and modern science and technology, Anhui Shengyang Medical Technology Co., Ltd. has become a leader in the field of acupuncture needle production with its excellent manufacturing process and unremitting pursuit of quality. Today, we'll delve into how companies hone every step of the manufacturing process to ensure that every acupuncture needle produced meets the highest standards of safety and effectiveness.

Strict selection of raw materials

It all starts with selecting the highest quality raw materials. Anhui Shengyang Medical Technology Co., Ltd. selected high-quality stainless steel as the main material of acupuncture needles, this material not only has excellent biocompatibility, but also corrosion resistance, high strength, to ensure that the needle body in the use of the process to maintain good elasticity and sharp.

High precision machining

After precision machining, slender metal rods are made into preliminary needle shapes. At this stage, it is necessary to ensure that each needle is strictly in accordance with the design specifications, whether it is the sharpness of the tip or the diameter of the needle body, it is very precise.

Surface treatment and polishing

In order to reduce the resistance during puncture and improve the comfort of patients, the surface of acupuncture needles should be carefully cleaned and deburred. Next, nano-micron laser scoring technology is used to carve spiral grooves on the surface of the needle body, which can not only reduce the pain of acupuncture, but also increase the lubricity between the needle and the tissue. Finally, the surface of the needle body is further polished by plasma coating treatment technology, making it smoother and reducing the risk of skin damage.

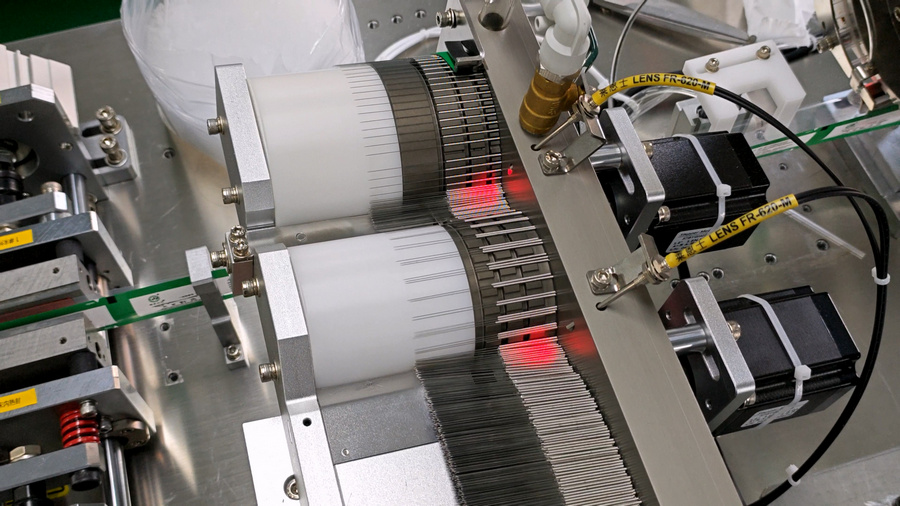

Handle winding process

The design of the needle handle is equally important. It must not only be convenient for the physician to operate, but also ensure stability during treatment. Anhui Shengyang Medical Technology Co., Ltd. uses automatic winding technology to make the needle handle firmly fixed on the needle body, and provides different material choices according to demand, such as plastic or metal, to adapt to various clinical environments.

Strict inspection process

After the completion of all production steps, each batch of acupuncture needles will go through a strict inspection procedure. Including but not limited to appearance inspection, size measurement, hardness testing, etc., only fully qualified products can enter the packaging process. In addition, all products are sterilized to ensure a sterile state and ensure patient safety.

Conclusion

From the selection of raw materials to the inspection of the final product, every link is the persistent pursuit of quality. With such a rigorous attitude and exquisite technology, Anhui Shengyang Medical Technology Co., Ltd. continues to promote the progress of acupuncture needle manufacturing process, providing safer and more effective acupuncture solutions for users around the world. In the future, we will continue to be committed to technological innovation to make the ancient acupuncture therapy full of new vitality and vitality.

新闻栏目

最新文章

-

时间:2025/01/21

-

时间:2025/01/21

Shengyang Medical in acupuncture needle production process ingenuity

-

时间:2025/01/21

Explore the development of acupuncture needles from ancient times to present

-

时间:2025/01/21

-

时间:2025/01/21

Build a strong security line, and Shengyang Medical treatment will move forward steadily

-

时间:2025/01/21

Escort acupuncture treatment with professional quality - Shengyang Medical Department